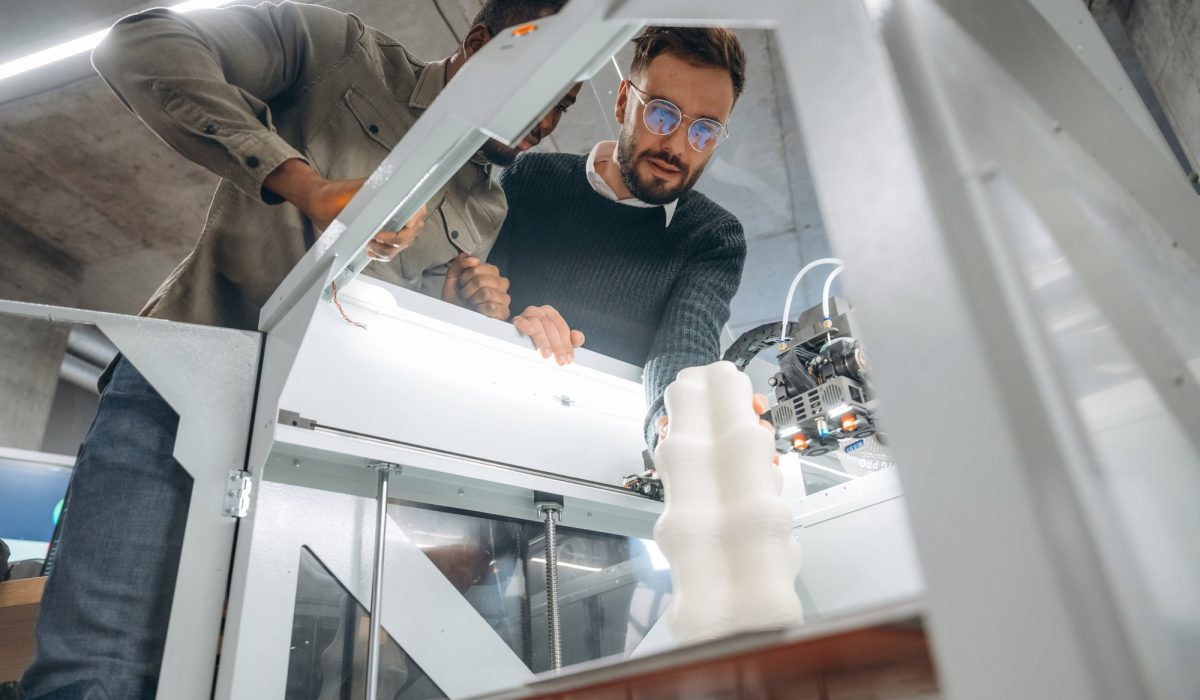

Adoption of 3D printing across industries has reached a pivotal moment. This new printer technology is now capable of producing highly detailed, customized components at a pace and cost that makes sense for enterprise use. With innovations like multi-material printing and AI-driven optimization, organizations are exploring new ways to solve operational challenges. Modern businesses stand to gain from implementing this technology as part of a wider digital transformation.

Integrating 3D printers into enterprise print infrastructure requires more than simply purchasing the latest equipment. Businesses must think about long-term maintenance, service strategies, and cost controls. Without the right support framework, downtime, calibration issues, and material waste can quickly reduce ROI. That’s why companies are increasingly turning to managed print experts to help them adopt and maintain new printer technology efficiently.

The Rise of Multi-Material and Multi-Color 3D Printing

Modern 3D printers now handle multiple materials and colors in a single print job. This new printer technology eliminates the need for post-processing steps like assembly or painting, saving both time and labor. Complex prototypes and functional end-use parts can now emerge from one machine, fully finished and ready for use. Engineering, healthcare, and aerospace sectors are already applying these features to improve workflows.

Support for different materials such as PLA, PETG, and even metal-infused filaments gives businesses greater versatility. Enterprises can produce more durable or flexible parts based on functional needs without swapping out machines. This reduces the burden on IT and operations teams who would otherwise manage multiple devices. A centralized 3D printer setup becomes more feasible with this kind of capability.

While these advancements open new doors, they also require proactive printer management. Precision calibration, firmware updates, and routine maintenance become more important than ever. Expert service providers help ensure machines continue to operate at optimal levels without delays or degradation in print quality.

With multi-functionality comes complexity, and not all in-house teams are equipped to manage it. That’s why organizations are now looking toward managed print services that understand the nuances of supporting advanced 3D printer hardware. These providers help reduce device failure, manage part replacements, and offer insights to improve uptime.

Integration with CAD and Cloud-Based Workflows With New 3D Printer Technology

The latest 3D printer technology now integrates smoothly with cloud-based CAD tools and workflow software. Teams can access models from anywhere and send them directly to print queues, increasing speed and collaboration. Engineers can iterate on product design without waiting on third-party vendors or shipping delays. This accelerates time-to-market for physical products and prototypes.

As 3D printers connect directly to design systems, the print environment becomes more data-driven. Analytics tools can monitor usage patterns, predict maintenance needs, and assess material efficiency. These insights are valuable to business leaders aiming to optimize production schedules and reduce waste. The synergy between software and hardware drives smarter decision-making at scale.

However, integration adds new layers of network security, firmware management, and print data governance. IT teams must manage access controls, monitor network traffic, and ensure intellectual property remains secure. Without proper oversight, connected printers can expose businesses to cybersecurity risks.

Managed service partners offer a secure way to support cloud-connected print devices. With experience in networked environments, they ensure compatibility with enterprise IT systems and help lock down access. Businesses benefit from the convenience of modern print workflows without sacrificing control or security.

Enterprise Benefits of Rapid Prototyping Through New Printer Technology

3D printing enables fast prototyping cycles, allowing businesses to bring ideas to life in days rather than weeks. This shortens the feedback loop between design, production, and testing. Marketing teams can develop physical samples for trade shows, while engineers refine designs based on real-world use cases. Rapid iteration boosts innovation across departments.

Small-batch production using new printer technology also reduces reliance on external suppliers. Enterprises avoid long lead times, minimum order quantities, and costly design changes mid-production. This helps businesses stay agile in fast-changing markets. Internal prototyping also improves intellectual property protection.

Without consistent maintenance and calibration, however, prototypes may suffer from warping, dimensional inaccuracies, or poor surface finish. These defects slow down the design process and reduce confidence in printed parts. Preventative servicing helps maintain the accuracy and consistency critical to effective prototyping.

Partnering with a knowledgeable print services provider ensures the equipment always runs within spec. Regular diagnostics, firmware updates, and part replacements keep machines production-ready. When speed and quality matter most, expert support ensures 3D printers meet enterprise expectations.

Reducing Waste and Cost with Additive Manufacturing

Unlike subtractive manufacturing, which removes material from a solid block, 3D printing builds parts layer by layer. This method significantly reduces material waste and can lower production costs. Businesses gain efficiency by using only what’s needed for each part. This sustainability advantage is especially important for companies pursuing green initiatives.

Costs also come down when using in-house 3D printers instead of outsourcing production. Printing custom parts on demand eliminates overproduction and unused inventory. Teams can shift from bulk manufacturing to just-in-time workflows. The financial impact grows over time with consistent use.

However, maximizing cost savings requires proper oversight of filament usage, print accuracy, and machine health. Misprints, failed jobs, and underutilized capacity can quietly drive up operational costs. Businesses must balance the benefits of new printer technology with a solid service strategy.

Service providers help enterprises reduce waste by monitoring usage and identifying inefficiencies. With detailed reporting and support, businesses can spot trends and adjust workflows. Managed print experts contribute to both cost savings and sustainability goals.

Extending Equipment Life through Preventative Maintenance

3D printers, like traditional multifunction devices, require routine upkeep to stay in top shape. Print heads, motors, belts, and sensors must be cleaned, aligned, or replaced at regular intervals. Preventative printer maintenance extends device lifespan and prevents unexpected downtime. Organizations benefit from greater ROI when machines run reliably over time.

Delays from equipment failure can disrupt operations, delay product launches, and increase frustration among staff. Many of these issues stem from neglected maintenance or improper handling. Staff may lack the training to diagnose and fix internal print errors. A reactive service model puts business continuity at risk.

Managed print services make it easier for businesses to stay ahead of maintenance needs, even with new printer technology. Through custom service plans, businesses can align maintenance schedules with production demands. Expert technicians ensure that printers support growth instead of slowing it down.

Building a Scalable 3D Printing Infrastructure

As demand for in-house production increases, businesses need 3D printer fleets that can scale. Adding devices across locations introduces challenges in standardization, supply management, and user training. Without centralized oversight, organizations risk inconsistency, inefficiency, and increased service costs. A scalable model requires structure and expert guidance.

Supply management becomes a logistical hurdle without a unified procurement and monitoring system. Consumables like filament, nozzles, and build plates must be stocked and tracked. Print job queuing, access control, and reporting need to be integrated across teams. Consistency ensures better forecasting and cost control.

Device standardization reduces the learning curve for staff and simplifies troubleshooting. With uniform hardware and software environments, IT departments save time during setup and support. Scaling becomes easier when every machine follows the same performance benchmarks. Teams can collaborate across locations with minimal disruption.

Working with a managed print provider gives enterprises the tools and guidance to scale effectively. Centralized dashboards, inventory management, and multi-site service coverage allow for seamless growth. Businesses gain the flexibility to expand printing capabilities without the growing pains.

Optimize New Printer Technology with the Right Support

Innovative 3D printing tools offer immense potential for enterprises, but only when paired with thoughtful infrastructure and expert service. Businesses that proactively manage their printers avoid common pitfalls like downtime, supply waste, and inconsistent output. With support from experienced professionals, companies can confidently adopt new printer technology and use it to gain a competitive edge.

Partnering with a provider that understands complex printer environments allows organizations to focus on what matters—product development, customer experience, and operational excellence. Through on-site diagnostics, preventative maintenance, and custom service plans, these specialists help protect your investment and drive long-term value.

Looking to optimize your print infrastructure and embrace new 3D printer technology without compromising performance or budget? Onsite Laser Medic delivers enterprise-level managed print services designed to keep your advanced devices running efficiently. Let our experts help you unlock the full potential of your print environment today.